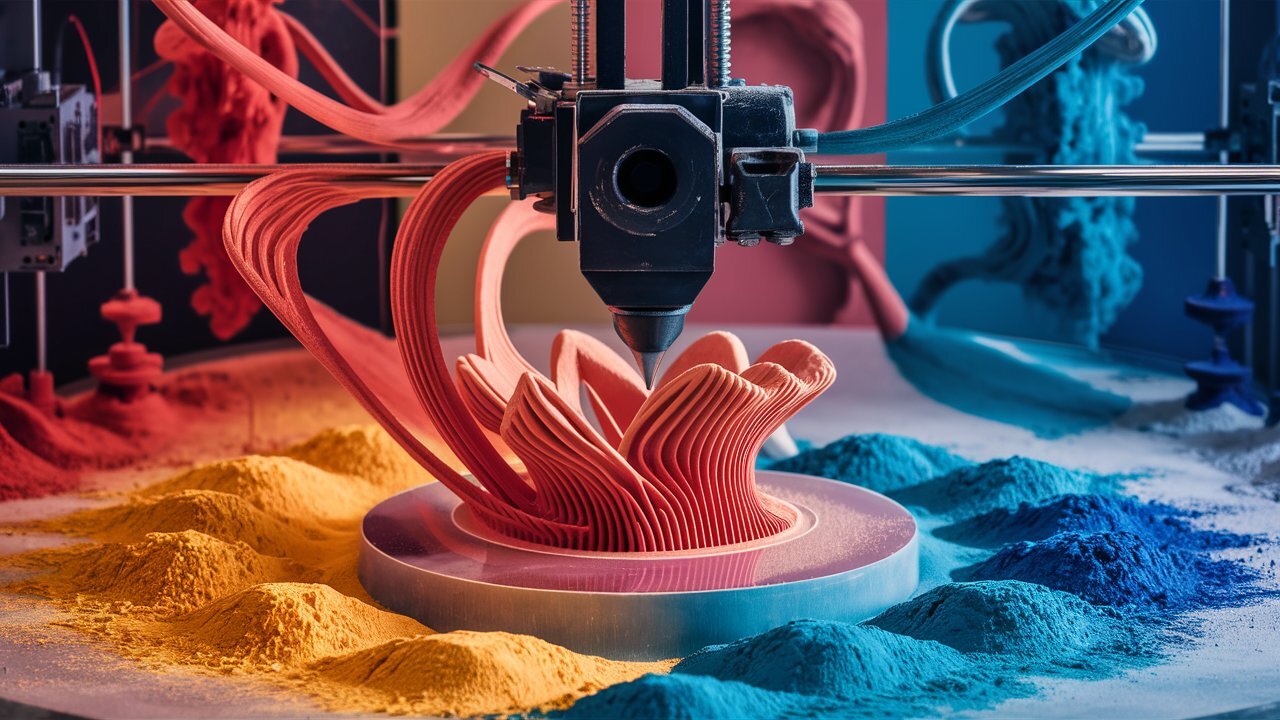

Scientists at the University of Duysburg Essen completed six years of research in the field of 3D printing with powder materials. The main attention was paid to the process of laser sintering of powders, which is used to create complex details in aviation, medicine and instrumental production.

During the work, an international open research was created in its kind. In 32 laboratories of different countries, standardized metal and polymer parts were manufactured, including samples with the addition of nanoparticles. The purpose of the experiment was to study the influence of the properties of materials, equipment parameters and process control on the quality of finished products.

The data obtained open access to detailed information about the entire production chain – from the choice and preparation of powders to the characteristics of ready -made components. This allows you to form reliable standards, quickly introduce new materials and purposefully improve production processes.

The results of the study will be available in the open form from November 11, 2025, and also published in the special issue of Advanced Engineering Materials. The data is designed to become a guideline for both science and industry, ensuring the comparison of complex processes between different materials and laboratories.