The development uses the laser-induced discharge plasma (LDP) method, which is different from traditional ASML technology. The new approach simplifies the equipment design, makes it more energy-efficient, and reduces production costs. According to preliminary data, mass production of such machines may begin in 2026.

Major Chinese chip manufacturer SMIC still faces difficulties with the mass production of 5nm semiconductors due to high costs and low yields. This also limits Huawei’s capabilities, which currently cannot surpass the 7nm threshold. The new equipment being developed in China will allow the use of advanced 13.5nm EUV lithography, which will significantly accelerate the development of the country’s semiconductor industry.

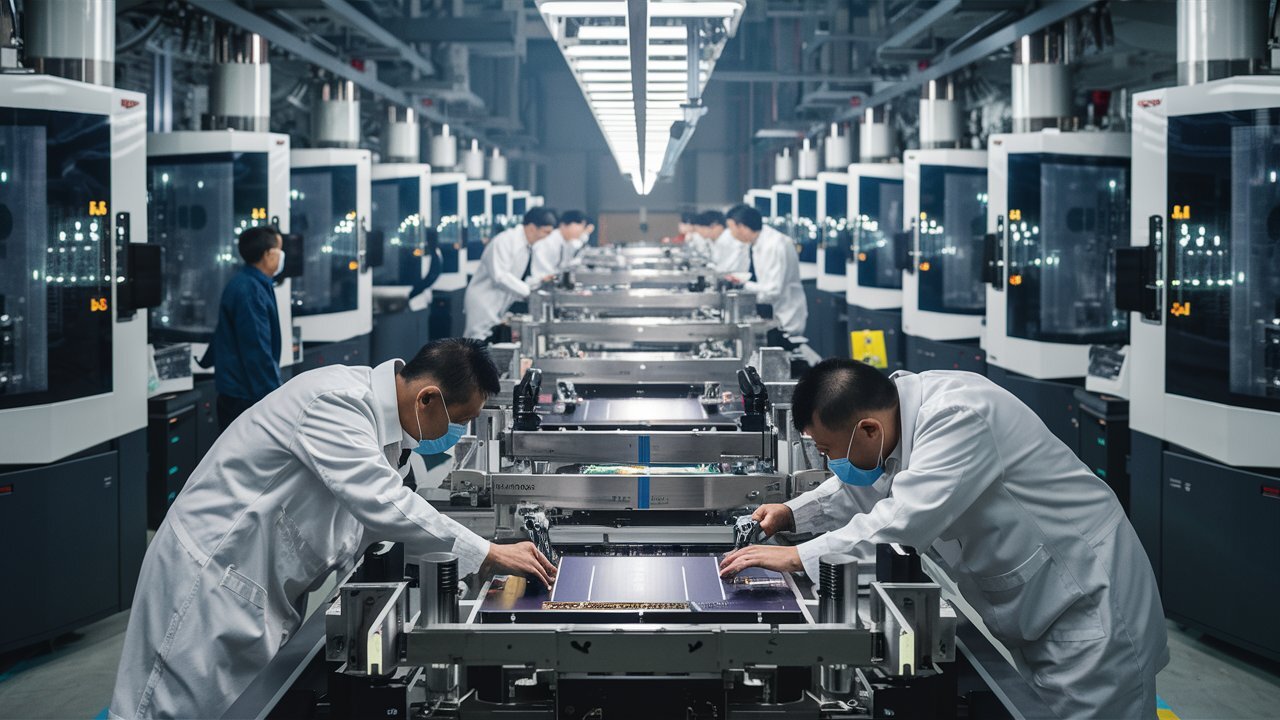

Prototype testing is already underway at Huawei’s research center in Dongguan. It is reported that the system uses the method of tin evaporation between electrodes, followed by plasma ionization at high voltage. This process is more accessible and less energy-intensive compared to European counterparts, making the technology promising for mass adoption.