A group of experts from RMIT-Melbournsky Royal Technological University in Australia-has developed a new 3D printing method of titanium, which combines the strength and plasticity of the material with a lower production cost. The new method allows you to create titanium parts that surpass traditional alloys in quality and accessibility, and this can become a revolution in the aerospace industry and medicine.

According to the RMIT press service, the problem of the uneven internal grain of titanium products printed on a 3D printer was solved through a new design that provides a homogeneous structure and increased strength. This allows you to reduce production costs by 29%. We are talking about columnar microstructures that can create weaknesses, making metal less reliable. According to the leading researcher Ryan Bruka, the team achieved solving a key technical problem, while reducing the costs.

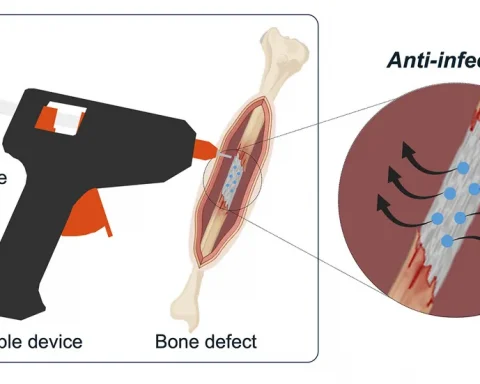

In the future, RMIT plans to focus on the production of components for the aerospace industry and medical devices, and also applied for a patent. For the introduction of technology, industrial partners and investors are needed.