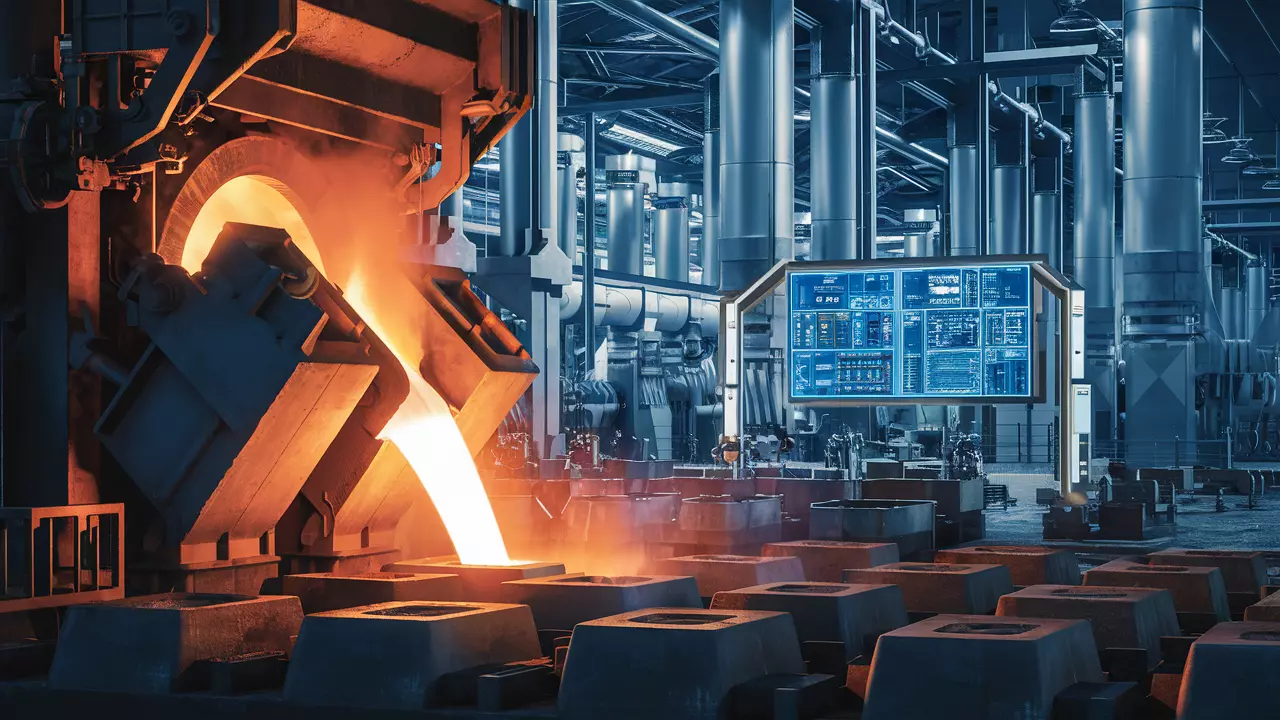

The press service of the Ministry of Education and Science of the Russian Federation reported that the specialists of the Samara Polytechnic, together with the Korolev Samara University, proposed a new method for mixing metal melts using electromagnetic impulses. Development will significantly improve the quality of cast products.

Traditional methods of mixing alloys – mechanical mixers, ultrasound or gas impulses – turned out to be less effective compared to a new approach. The technology is based on the use of a pulsed magnetic field, which is created by a special inducer coil.

As the dean of the faculty of mechanical engineering explained, Konstantin Nikitin, the field penetrates through the wall of non -metallic crucible and affects the melt, creating vortex currents. The interaction of these currents with the inductor field gives rise to electrodynamic forces that provide uniform mixing.

The advantage of the method lies in the possibility of accurate control of exposure parameters – frequency, strength and form of impulses. Currently, scientists are working on increasing the uniformity of the distribution of the magnetic field in the melt.

The results of the study are published in the journal “Foundry Production”.